Resolving the atomic structure information of the aromatic layers in coal plays a crucial role in understanding the generation mechanisms of NOx during coal combustion and further reducing the formation of NOx from the source. This study reveals the distribution of X-ray diffraction bands of superfine pulverized coal using a high-resolution synchrotron radiation X-ray Diffraction (HRXRD) facility, discussing the distribution of atomic distances and atomic density in aromatic layers through pair distribution function (PDF) methods. Furthermore, the influences of mechanochemistry on the evolution of atomic morphology are focused on. The results show that the PDF of coal gradually stabilizes when r > 8 Å, showing the short-range order of graphite-like structure. Additionally, due to the limitations of scanning angle and X-ray energy, atomic distances in aromatic layers for coal are significantly greater than that of pure graphene. Enhanced mechanochemical effects make the peaks 1, 2, and 3 of coal PDF more similar to graphene's by condensing alkyl side chains into smaller, regular aromatic layers when the particle size decreases. With the enhancement of mechanochemical effects, coals with different metamorphic degrees exhibit different aromatic evolution patterns. The aromaticity of NMG coal first decreases and then increases, while the aromaticity of YQ coal shows the opposite trend. The results can provide deeper insights into the atomic structure of coal macromolecular, which can facilitate the advancement of novel ultra-low NOx combustion methods and support the construction of precise coal macromolecular models.

| Published in | Journal of Energy and Natural Resources (Volume 13, Issue 2) |

| DOI | 10.11648/j.jenr.20241302.11 |

| Page(s) | 50-58 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2024. Published by Science Publishing Group |

Superfine Pulverized Coal, Mechanochemistry, HRXRD, PDF

Samples | Proximate analysis (ad) (wt %) | Ultimate analysis (ad) (wt %) | ||

|---|---|---|---|---|

YQ | M | 1.06 | C | 79.07 |

V | 7.98 | H | 3.47 | |

A | 12.43 | O | 1.01 | |

FC | 78.53 | N | 1.14 | |

S | 1.82 | |||

NMG | M | 14.72 | C | 54.82 |

V | 35.69 | H | 4.39 | |

A | 10.64 | O | 14.58 | |

FC | 38.95 | N | 0.63 | |

S | 0.22 | |||

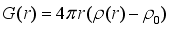

(1)

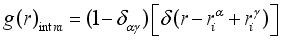

(1)  (2)

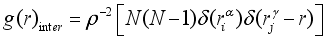

(2)  (3)

(3) Peak positions (Å) | ||||

|---|---|---|---|---|

NMG_12.6 | NMG_15.0 | NMG_25.9 | NMG_52.8 | |

Peak 1 | 1.75 | 1.77 | 1.78 | 1.79 |

Peak 2 | 3.09 | 3.00 | 2.94 | 3.17 |

Peak 3 | 4.60 | 4.50 | 4.54 | 4.62 |

Peak 4 | 5.69 | 5.77 | 5.78 | 5.76 |

Peak 6 | 7.26 | 7.25 | 7.32 | 7.32 |

YQ_5.4 | YQ_17.3 | YQ_24.0 | YQ_38.9 | |

Peak 1 | 1.75 | 1.74 | 1.75 | 1.78 |

Peak 2 | 3.45 | 3.44 | 3.44 | 3.46 |

Peak 3 | 4.57 | 4.57 | 4.58 | 4.52 |

Peak 4 | 5.96 | 6.16 | 6.08 | 5.98 |

Peak 6 | 7.45 | 7.48 | 7.53 | 7.57 |

NOx | Nitrogen Oxides |

HRXRD | High-Resolution Synchrotron Radiation X-ray Diffraction |

Pair Distribution Function | |

HRTEM | High Resolution Transmission Electron Microscope |

| [1] | Gao X, Chen H, Wei L, Pan P, Zhang K, Wu L. Performance assessment of a hydrothermal treatment-based sewage sludge-to-electricity system integrated with a coal-fired power plant. Energy Conversion and Management. 2024, 300, 117957. |

| [2] | Ogugua PC, Su H, Wang E. Synergistic blending of biomass, sewage sludge, and coal for enhanced bioenergy production: Exploring residue combinations and optimizing thermal conversion parameters. Journal of Environmental Management. 2024, 352, 120035. |

| [3] | Zhou F, Yu J, Wu C, Fu J, Liu J, Duan X. The application prospect and challenge of the alternative methanol fuel in the internal combustion engine. Science of the Total Environment. 2024, 913, 169708. |

| [4] | Niu S, Han K, Lu C. Release of sulfur dioxide and nitric oxide and characteristic of coal combustion under the effect of calcium based organic compounds. Chemical Engineering Journal. 2011, 168(1), 255-61. |

| [5] | Glarborg P, Miller JA, Ruscic B, Klippenstein SJ. Modeling nitrogen chemistry in combustion. Progress in Energy and Combustion Science. 2018, 67, 31-68. |

| [6] | Phiri Z, Everson RC, Neomagus HWJP, Wood BJ. Transformation of nitrogen functional forms and the accompanying chemical-structural properties emanating from pyrolysis of bituminous coals. Applied Energy. 2018, 216, 414-27. |

| [7] | Yu J, Lucas JA, Wall TF. Formation of the structure of chars during devolatilization of pulverized coal and its thermoproperties: A review. Progress in Energy and Combustion Science. 2007, 33(2), 135-70. |

| [8] | Zhang L, Hu S, Xu K, Jiang L, Wang Y, Su S, et al. Study on the structural evolution of semi-chars and their solvent extracted materials during pyrolysis process of a Chinese low-rank coal. Fuel. 2018, 214, 363-8. |

| [9] | Molina A, Murphy JJ, Winter F, Haynes BS, Blevins LG, Shaddix CR. Pathways for conversion of char nitrogen to nitric oxide during pulverized coal combustion. Combustion & Flame. 2009, 156(3), 574-87. |

| [10] | Feng B, Bhatia SK, Barry JC. Structural ordering of coal char during heat treatment and its impact on reactivity. Carbon. 2002, 40(4), 481-96. |

| [11] | Liang D, Singer S. Pore-resolving simulations to study the impacts of char morphology on zone II combustion and effectiveness factor models. Combustion and Flame. 2021, 229, 111405. |

| [12] | Badaczewski F, Loeh MO, Pfaff T, Dobrotka S, Wallacher D, Clemens D, et al. Peering into the structural evolution of glass-like carbons derived from phenolic resin by combining small-angle neutron scattering with an advanced evaluation method for wide-angle X-ray scattering. Carbon. 2019, 141, 169-81. |

| [13] | Zickler GA, Smarsly B, Gierlinger N, Peterlik H, Paris O. A reconsideration of the relationship between the crystallite size La of carbons determined by X-ray diffraction and Raman spectroscopy. Carbon. 2006, 44(15), 3239-46. |

| [14] | Chatterjee A, Maiti P, Siddiqi H, Mishra A, Durga Prasad G, Meikap BC. Interpreting crystallographic and microcrystalline structural effect for demineralization of low-grade thermal coal in multi-stage chemical leaching: A cleaner combustion approach. Powder Technology. 2024, 435. |

| [15] | Xu X, Yuan S, Li J, Guo S. Microscopic mechanism of carbon oxides formation during long-flame coal oxidation at molecular scale. Fuel. 2024, 362. |

| [16] | Ismagilov ZR, Shigabutdinov AK, Presnyakov VV, Idrisov MR, Khramov AA, Urazaykin AS, et al. Developing Additives Based on Russian Coal for the Thermal Hydrocracking of Heavy Tar 4. X-ray Diffraction Study of Coal Composition. Coke and Chemistry. 2023, 66(10), 485-9. |

| [17] | Terban MW, Billinge SJL. Structural Analysis of Molecular Materials Using the Pair Distribution Function. Chemical Reviews. 2022, 122(1), 1208-72. |

| [18] | Wertz DL, Bissell M. One-dimensional description of the average polycyclic aromatic unit in Pocahontas No. 3 coal: an X-ray scattering study. Fuel. 1995, 74(10), 1431-5. |

| [19] | Zhang Z. Structure and dynamics in brown coal matrix during moisture removal process by molecular dynamics simulation. Molecular Physics. 2011, 109(3), 447-55. |

| [20] | Cavallari C, Rols S, Fischer HE, Brunelli M, Gaboardi M, Magnani G, et al. Neutron scattering study of nickel decorated thermally exfoliated graphite oxide. International Journal of Hydrogen Energy. 2019, 44(59), 30999-1007. |

| [21] | Castro-Marcano F, Winans RE, Chupas P, Chapman K, Calo JM, Watson JK, et al. Fine structure evaluation of the pair distribution function with molecular models of the Argonne Premium coals. Energy and Fuels. 2012, 26, 4336-45. |

| [22] | Grigoriew H. Interpretation of the pair function for laminar amorphous materials in the case of coals. I. Model considerations. Journal of Applied Crystallography 1988, 21(2), 97-101. |

| [23] | Liu J, Jiang X, Shen J, Zhang H. NO emissions from oxidizer-staged combustion of superfine pulverized coal in the O2/CO2 atmosphere. Energy and Fuels. 2014, 28(8), 5497-504. |

| [24] | Liu J, Jiang X, Shen J, Zhang H. Pyrolysis of superfine pulverized coal. Part 3. Mechanisms of nitrogen-containing species formation. Energy Conversion and Management. 2015, 94, 130-8. |

| [25] | Shen J, Liu J, Xing Y, Zhang H, Luo L, Jiang X. Application of TG-FTIR analysis to superfine pulverized coal. Journal of Analytical and Applied Pyrolysis. 2018, 133, 154-61. |

| [26] | ASTMD5373−16, Standard Test Methods for Determination of Carbon, Hydrogen and Nitrogen in Analysis Samples of Coal and Carbon in Analysis Samples of Coal and Coke; ASTM International: West Conshohocken, PA, 2016. |

| [27] | Pol VG, Calderon-Moreno JM, Chupas PJ, Winans RE, Thiyagarajan P. Synthesis of monodispersed prolate spheroid shaped paramagnetic carbon. Carbon. 2009, 47(4), 1050-5. |

| [28] | Wang C, Zeng F, Li C, Xu Q, Chen P. Insight into the molecular structural evolution of a series of medium-rank coals from China by XRD, Raman and FTIR. Journal of Molecular Structure. 2024, 1303. |

| [29] | Saikia BK. Inference on carbon atom arrangement in the turbostatic graphene layers in Tikak coal (India) by X-ray pair distribution function analysis. International Journal of Oil, Gas and Coal Technology. 2010, 3(4), 362-73. |

| [30] | Luo L, Yao W, Liu J, Zhang H, Ma J, Jiang X. The effect of the grinding process on pore structures, functional groups and release characteristic of flash pyrolysis of superfine pulverized coal. Fuel. 2019, 235, 1337-46. |

| [31] | Zhong Q, Mao Q, Zhang L, Xiang J, Xiao J, Mathews JP. Structural features of Qingdao petroleum coke from HRTEM lattice fringes: Distributions of length, orientation, stacking, curvature, and a large-scale image-guided 3D atomistic representation. Carbon. 2018, 129, 790-802. |

APA Style

Yang, X., Zhou, Z., Wu, F., Liu, J. (2024). Dissecting of Atomic Morphology of Superfine Pulverized Coal Based on X-ray Pair Distribution Function. Journal of Energy and Natural Resources, 13(2), 50-58. https://doi.org/10.11648/j.jenr.20241302.11

ACS Style

Yang, X.; Zhou, Z.; Wu, F.; Liu, J. Dissecting of Atomic Morphology of Superfine Pulverized Coal Based on X-ray Pair Distribution Function. J. Energy Nat. Resour. 2024, 13(2), 50-58. doi: 10.11648/j.jenr.20241302.11

AMA Style

Yang X, Zhou Z, Wu F, Liu J. Dissecting of Atomic Morphology of Superfine Pulverized Coal Based on X-ray Pair Distribution Function. J Energy Nat Resour. 2024;13(2):50-58. doi: 10.11648/j.jenr.20241302.11

@article{10.11648/j.jenr.20241302.11,

author = {Xiuchao Yang and Zining Zhou and Fang Wu and Jiaxun Liu},

title = {Dissecting of Atomic Morphology of Superfine Pulverized Coal Based on X-ray Pair Distribution Function

},

journal = {Journal of Energy and Natural Resources},

volume = {13},

number = {2},

pages = {50-58},

doi = {10.11648/j.jenr.20241302.11},

url = {https://doi.org/10.11648/j.jenr.20241302.11},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.jenr.20241302.11},

abstract = {Resolving the atomic structure information of the aromatic layers in coal plays a crucial role in understanding the generation mechanisms of NOx during coal combustion and further reducing the formation of NOx from the source. This study reveals the distribution of X-ray diffraction bands of superfine pulverized coal using a high-resolution synchrotron radiation X-ray Diffraction (HRXRD) facility, discussing the distribution of atomic distances and atomic density in aromatic layers through pair distribution function (PDF) methods. Furthermore, the influences of mechanochemistry on the evolution of atomic morphology are focused on. The results show that the PDF of coal gradually stabilizes when r > 8 Å, showing the short-range order of graphite-like structure. Additionally, due to the limitations of scanning angle and X-ray energy, atomic distances in aromatic layers for coal are significantly greater than that of pure graphene. Enhanced mechanochemical effects make the peaks 1, 2, and 3 of coal PDF more similar to graphene's by condensing alkyl side chains into smaller, regular aromatic layers when the particle size decreases. With the enhancement of mechanochemical effects, coals with different metamorphic degrees exhibit different aromatic evolution patterns. The aromaticity of NMG coal first decreases and then increases, while the aromaticity of YQ coal shows the opposite trend. The results can provide deeper insights into the atomic structure of coal macromolecular, which can facilitate the advancement of novel ultra-low NOx combustion methods and support the construction of precise coal macromolecular models.

},

year = {2024}

}

TY - JOUR T1 - Dissecting of Atomic Morphology of Superfine Pulverized Coal Based on X-ray Pair Distribution Function AU - Xiuchao Yang AU - Zining Zhou AU - Fang Wu AU - Jiaxun Liu Y1 - 2024/06/13 PY - 2024 N1 - https://doi.org/10.11648/j.jenr.20241302.11 DO - 10.11648/j.jenr.20241302.11 T2 - Journal of Energy and Natural Resources JF - Journal of Energy and Natural Resources JO - Journal of Energy and Natural Resources SP - 50 EP - 58 PB - Science Publishing Group SN - 2330-7404 UR - https://doi.org/10.11648/j.jenr.20241302.11 AB - Resolving the atomic structure information of the aromatic layers in coal plays a crucial role in understanding the generation mechanisms of NOx during coal combustion and further reducing the formation of NOx from the source. This study reveals the distribution of X-ray diffraction bands of superfine pulverized coal using a high-resolution synchrotron radiation X-ray Diffraction (HRXRD) facility, discussing the distribution of atomic distances and atomic density in aromatic layers through pair distribution function (PDF) methods. Furthermore, the influences of mechanochemistry on the evolution of atomic morphology are focused on. The results show that the PDF of coal gradually stabilizes when r > 8 Å, showing the short-range order of graphite-like structure. Additionally, due to the limitations of scanning angle and X-ray energy, atomic distances in aromatic layers for coal are significantly greater than that of pure graphene. Enhanced mechanochemical effects make the peaks 1, 2, and 3 of coal PDF more similar to graphene's by condensing alkyl side chains into smaller, regular aromatic layers when the particle size decreases. With the enhancement of mechanochemical effects, coals with different metamorphic degrees exhibit different aromatic evolution patterns. The aromaticity of NMG coal first decreases and then increases, while the aromaticity of YQ coal shows the opposite trend. The results can provide deeper insights into the atomic structure of coal macromolecular, which can facilitate the advancement of novel ultra-low NOx combustion methods and support the construction of precise coal macromolecular models. VL - 13 IS - 2 ER -